1. Conventional Shuttering

2. MIVAN ( Aluform ) Shuttering

1. Conventional Shuttering

Conventional shuttering, also known as traditional formwork, is a construction technique that uses temporary molds to support wet concrete until it sets. It’s a common and oldest method for construction of concrete buildings.

Characteristic of Conventional Shuttering

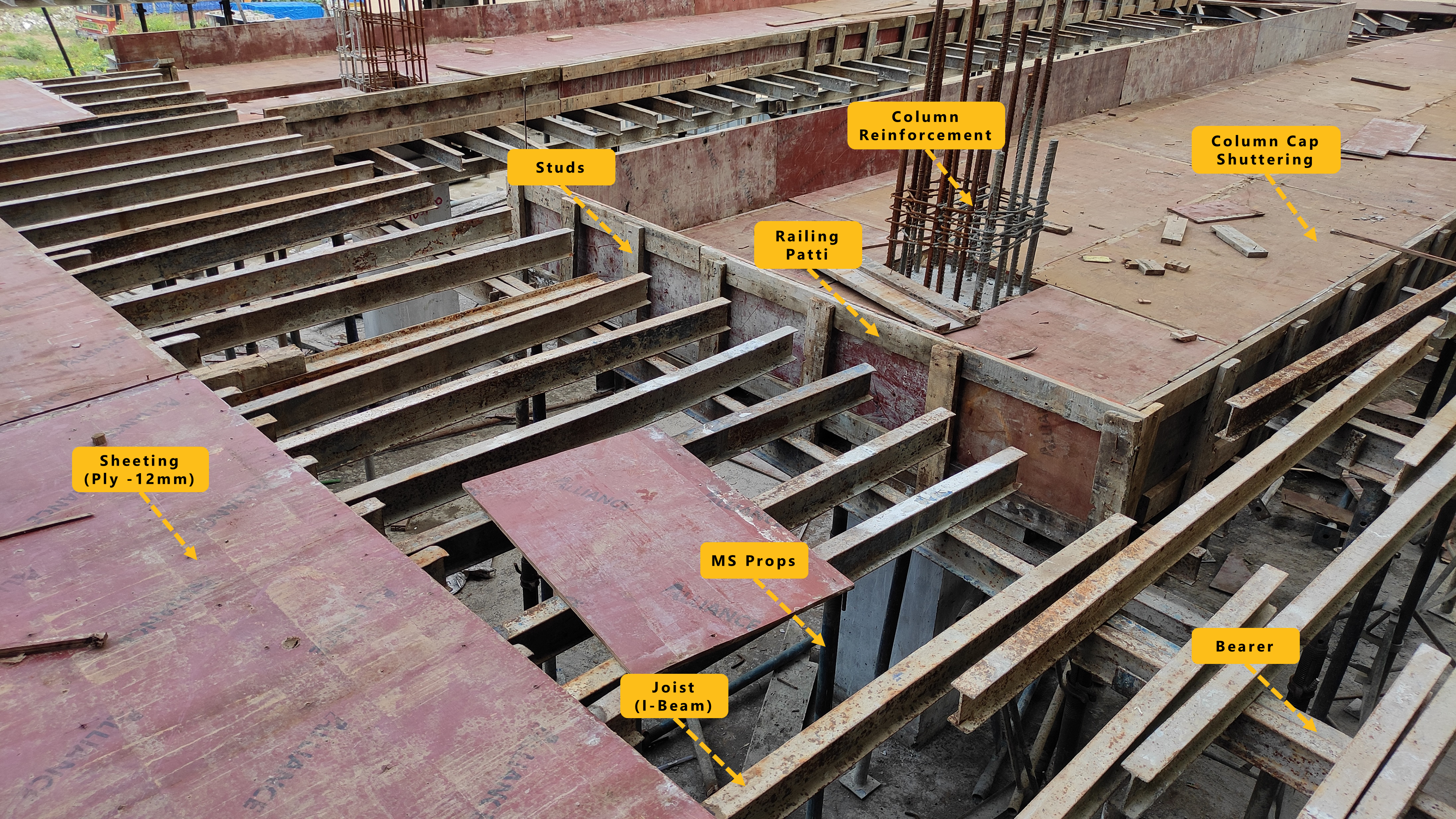

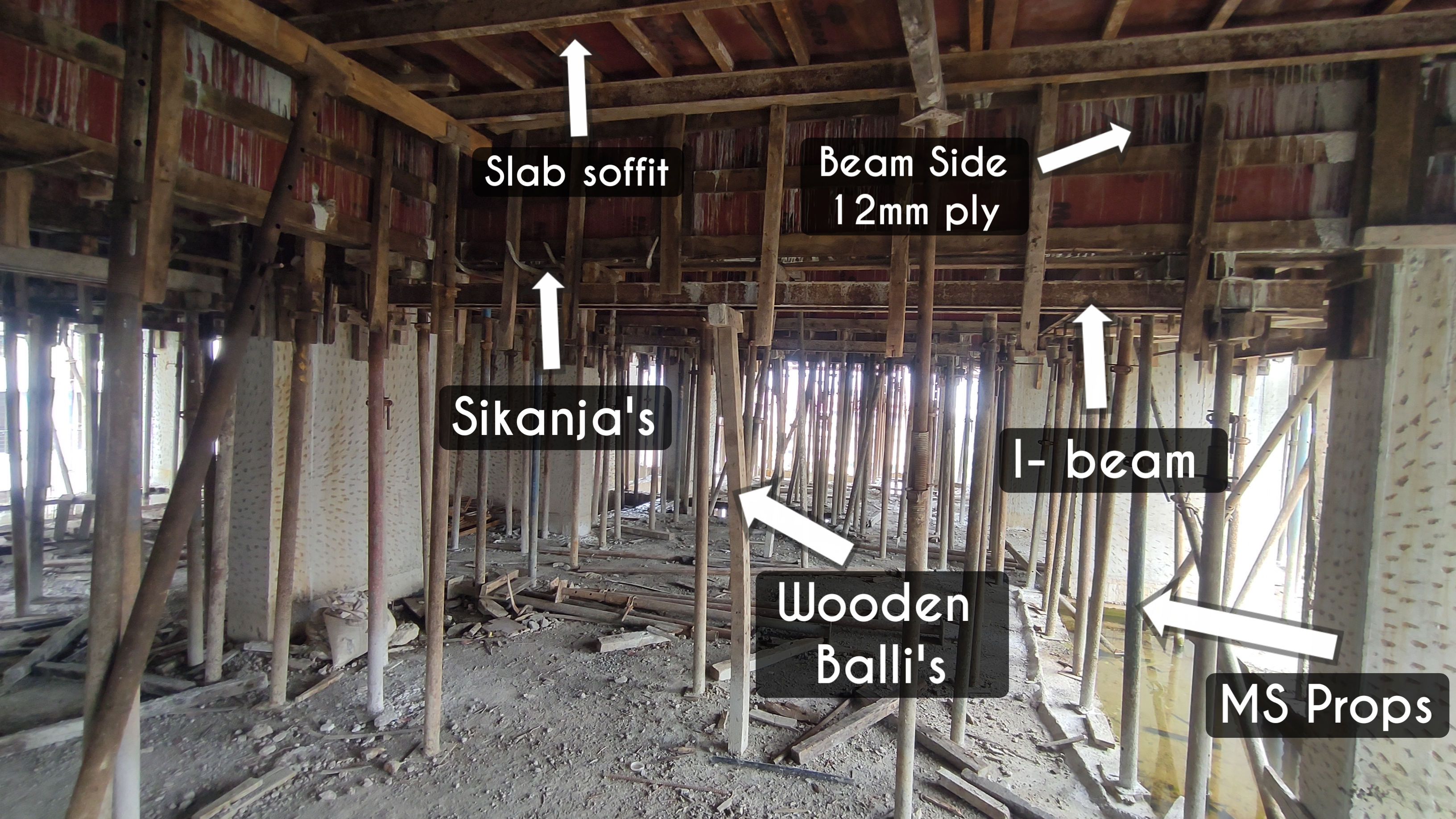

1. Conventional Shuttering system is made up of structural timber elements and plywood.

2. This system is preferred for smaller and custom projects because of its flexibility.

3.The flexibility allows for creativity and innovation in architectural designs.

4. The slab cycle for conventional tional shuttering is typically 13–15 days

General materials used in conventional Shuttering:

1. Shuttering plywood (1220*2440*12)mm

2. Wooden Chavi (Joist)-3″*3″/3″*2″

3. MS square pipe (Joist) -40mm*40mm

4. ISMC or ISMB (Bearer)-4″

5. MS adjustable props

6. Support Waller with tie bolt (16mm)

7. Shikanja -2ft/2.5ft

8. Nails-2″/2.5″

9. Annealed Binding wire-18 gauge

10. Tripod

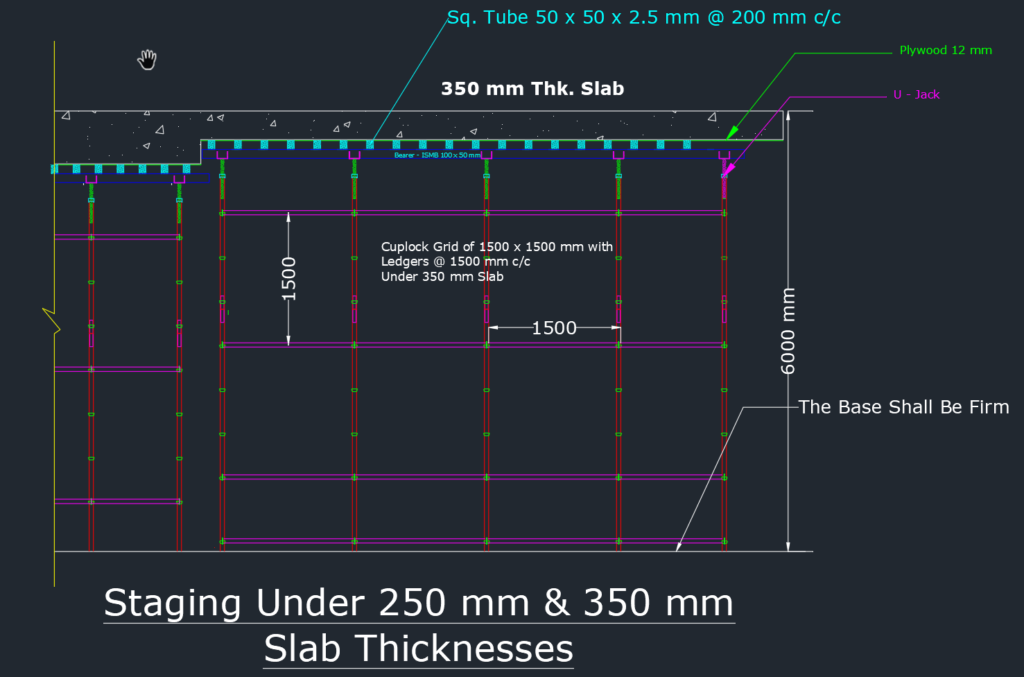

11. Cup-lock scaffolding system for staging

2. MIVAN Shuttering

- It was developed by MIVAN Company Ltd. from Malaysia in the 1990s for constructing mass housing projects in developing countries.

- MIVAN Company Ltd. began manufacturing these formworks, hence giving the name “MIVAN Technology”

- The system of aluminium forms (MIVAN) has been used widely in the construction of residential units and mass housing projects.

- It is fast, simple, adaptable and cost – effective. (we can achieve minimum 6-7 days slab cycle)

- This system is most suitable for Indian condition as a tailor–made aluminium formwork for cast–in–situ fully concrete structure.

- Just like Toothpaste has been renamed/known as Colgate because of its popularity, marketing, production, strategies etc. In same manner Aluminium Formwork is now known as Mivan.

Advantages of MIVAN formwork

- Uniformity in all components of structures.

- Replaces external block work with RCC which is eventually more safe and durable than block work

- Wall and slabs have smooth surface, which eliminates internal Plastering work

- Enables the construction of thinner walls, increasing usable floor space.

- This technology makes the structures more seismic resistant and durable as well

- Casting of all structural member is done at a single pour of concrete.

- Scrap value is high.

- Can be erected using unskilled labours and without the removing of props, deck panel can be removed

Limitations of MIVAN formwork

- It is rigid in design once placed, as any alteration becomes tough later.

- It requires uniform planning as well as uniform elevations to be cost effective.

- Due to presence of shear wall, heat of hydration is high.

- Initial cost is high ( Rs. 14000-16000 /Sqm )

- Not suitable for small scale projects.

- Due to box-type construction, contraction cracks are likely to appear.

- Services after completing become slightly difficult.

- The formwork requires number of spacer, wall ties etc. which are placed @ 2ft c/c; these produce problems such as seepage, leakages during monsoon.